Articles

Cooling Blower Placement and Maintenance for Molten Metal Pump Electric Motors in Foundry Environments

Electric motors operating molten metal pumps in foundry environments face challenging conditions, including high temperatures, dust, and debris. Effective cooling is crucial for motor reliability and longevity. This tech note provides guidelines for blower placement and maintenance to ensure optimal cooling performance in these harsh conditions.

Cover Gas in Secondary Aluminum Melting

In the realm of secondary aluminum melting, refining, and recycling, the utilization of cover gas stands as a pivotal technique for enhancing process efficiency and product quality. Cover gas, essentially an inert gas blanket, serves to shield molten aluminum from the detrimental effects of atmospheric oxygen interaction, mitigating oxidation and dross formation.

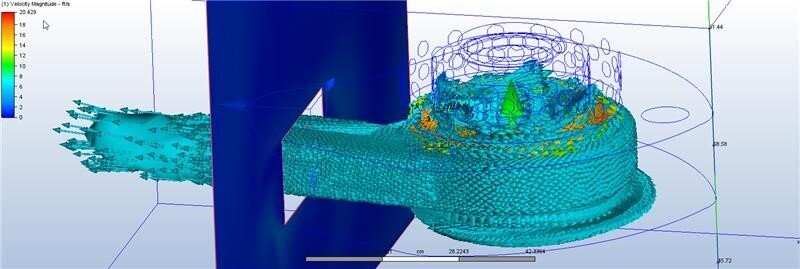

Quantitative Measurements and Characterization: The Key to Optimal Reverberatory Aluminum Melting Furnace Design

Designing an efficient reverberatory aluminum melting furnace is a complex undertaking. It requires careful consideration of various factors that directly affect its performance, energy consumption, and ultimately, your return on investment (ROI). Among these factors, the circulation pump’s sizing, placement, and control play a crucial role. Let’s explore how quantitative measurements and characterization lead to informed decisions in these areas, ensuring optimal furnace system design.

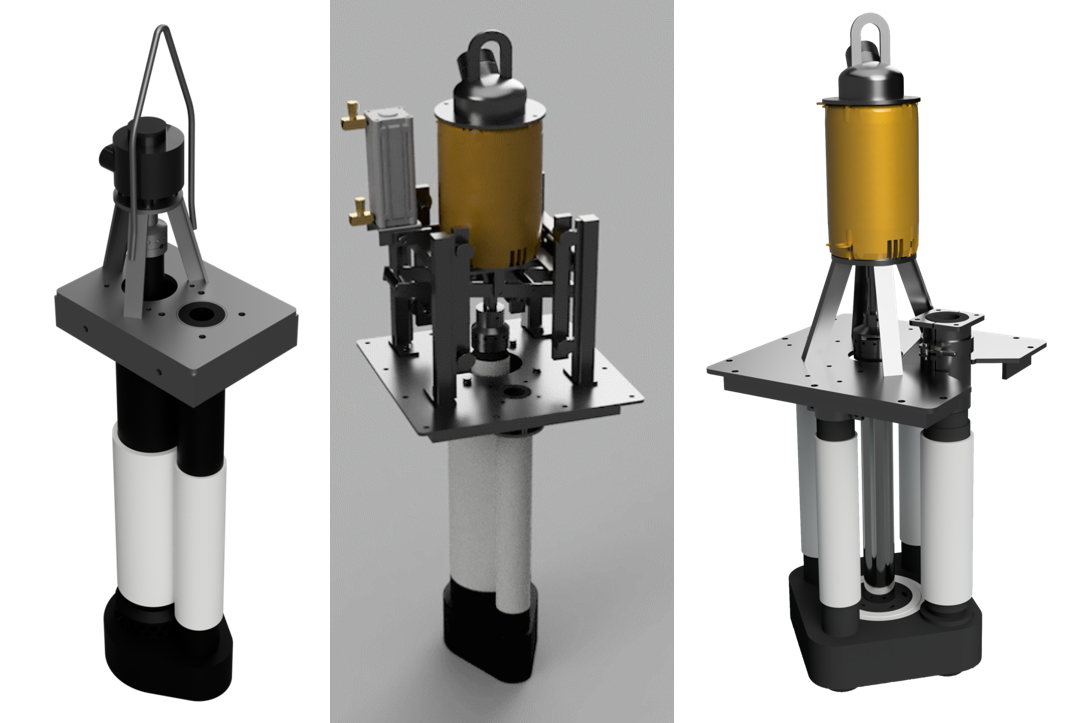

Transfer Pump Types

Closed, Dual Position, and Open Style transfer pumps are available in a range of sizes to accommodate any applications.

Intelligent Control for the Smart Foundry

Nearing the quarter of the 21st century, it seems technology is advancing faster and faster every year. Why shouldn’t your facility advance too? This post will provide some options for you to consider as you’re researching, designing, and improving your process.