Articles

Low Air Flow Freezes Pumps!

The primary reason for molten metal pump freezing is "slow starts." A slow-start is defined as slowly increasing the motor RPM. When a transfer pump is slow-started, the hot metal flows gradually into a cooler riser. As the metal temperature decreases, it solidifies or freezes inside the riser. This slow-start condition typically results in permanent damage and the need to rebuild the pump or at the very least replace the riser.

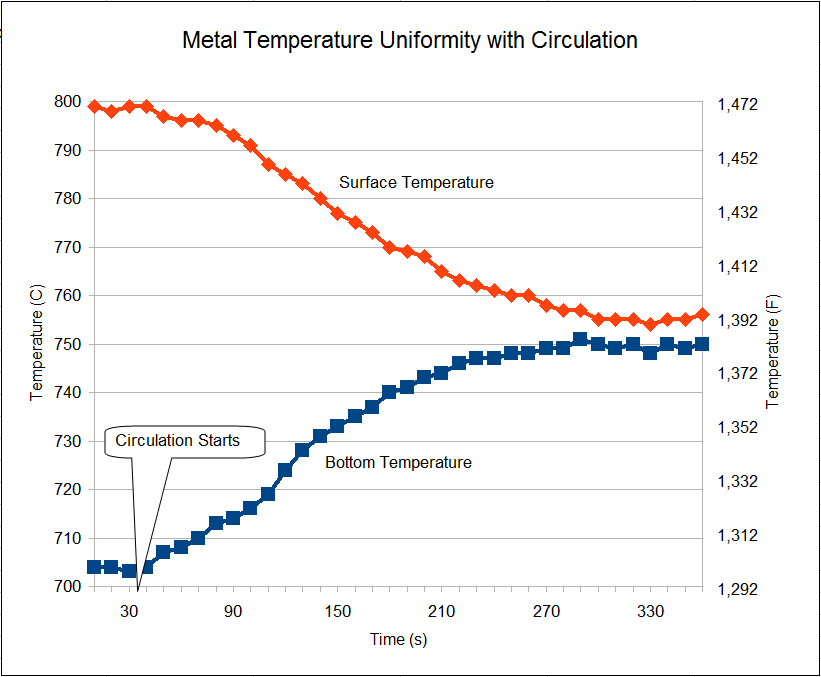

Why Should I Use a Circulation Pump?

In most real world applications, any one of these benefits results in savings that more than offsets the cost of a circulation pump. As an example, a properly sized and operated circulation pump can increase overall furnace throughput 15% and in some cases 30% for a small fraction of the cost of a furnace expansion project.