Articles

Best ROI for Your Furnace

In the world of aluminum production, achieving optimal energy efficiency and minimizing metal loss isn’t just about cost savings; it’s a critical step towards a greener future. If you’re looking to improve your bottom line and your environmental impact, optimizing your reverberatory aluminum melting furnace is a key strategy. Let’s explore how to maximize your ROI while supporting a more sustainable aluminum industry.

Understanding Rotary Degassing of Aluminum

Rotary degassing is a critical process in aluminum casting to remove dissolved hydrogen and impurities from molten aluminum. Dissolved hydrogen, if left unchecked, forms bubbles during solidification, leading to porosity in the final casting. This porosity negatively affects mechanical properties, reducing strength and ductility.

Low Air Flow Freezes Pumps!

The primary reason for molten metal pump freezing is "slow starts." A slow-start is defined as slowly increasing the motor RPM. When a transfer pump is slow-started, the hot metal flows gradually into a cooler riser. As the metal temperature decreases, it solidifies or freezes inside the riser. This slow-start condition typically results in permanent damage and the need to rebuild the pump or at the very least replace the riser.

Pump Installation Planning Guidelines - Part 1 - Start at 40,000 ft!

Planning a new pump installation is non-trivial and should be treated as a facilities project. It is best to start with a 40,000 ft view that includes all aspects of the operation. Every installation has unique challenges that are difficult to generalize in a tech note. Taking the time to identify every impact and risk, and developing risk mitigation plans are strongly recommended.

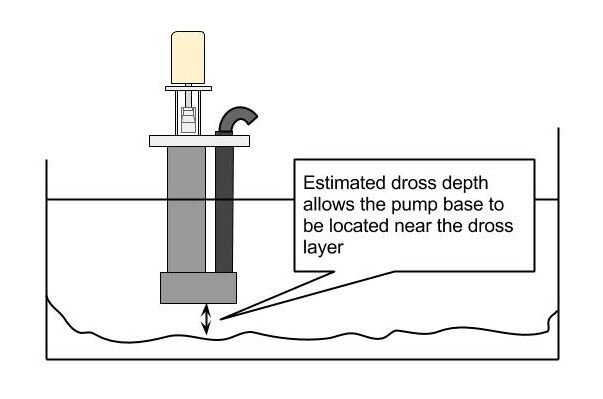

Manual Dross Pumping Best Practices

A manual dross pump, as compared to a fixed position dross pump, is a pump system that can be manually maneuvered around the zinc pot to remove or dredge the bottom dross. Manual dross pumps are typically used during regular maintenance cycles, while fixed position dross pumps operate continuously to remove top dross. Manual dross pumps are often used to supplement fix position top dross pump systems.

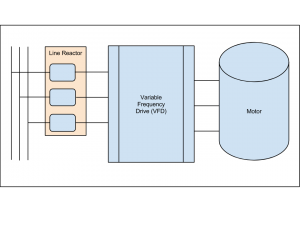

Line Reactors Improve Pump Motor Performance

Surprisingly few industrial facilities conduct power line quality assessments as part of routine maintenance. In a heavily mechanized environment, fast-transient power disruptions are common place. These fast transient events travel through out the power circuits and are stopped only by the power distribution transformers. This means that each individual piece of equipment must be designed to tolerate the electrical power environment in which it is installed.

Pump Installation - Lowering the Pump into the Molten Metal

This article reviews the standard procedure for introducing a pump into a molten metal bath.